Flat patterns deformation allowance bend tables working in both flat and as designed states and full associativity between part drawing and flat state.

Ptc sheet metal flat vs flange.

Pro e showed to be very inconsistent here with this.

Information regarding the difference of flange and flat wall features for sheet metal.

In the primary corner this happens once.

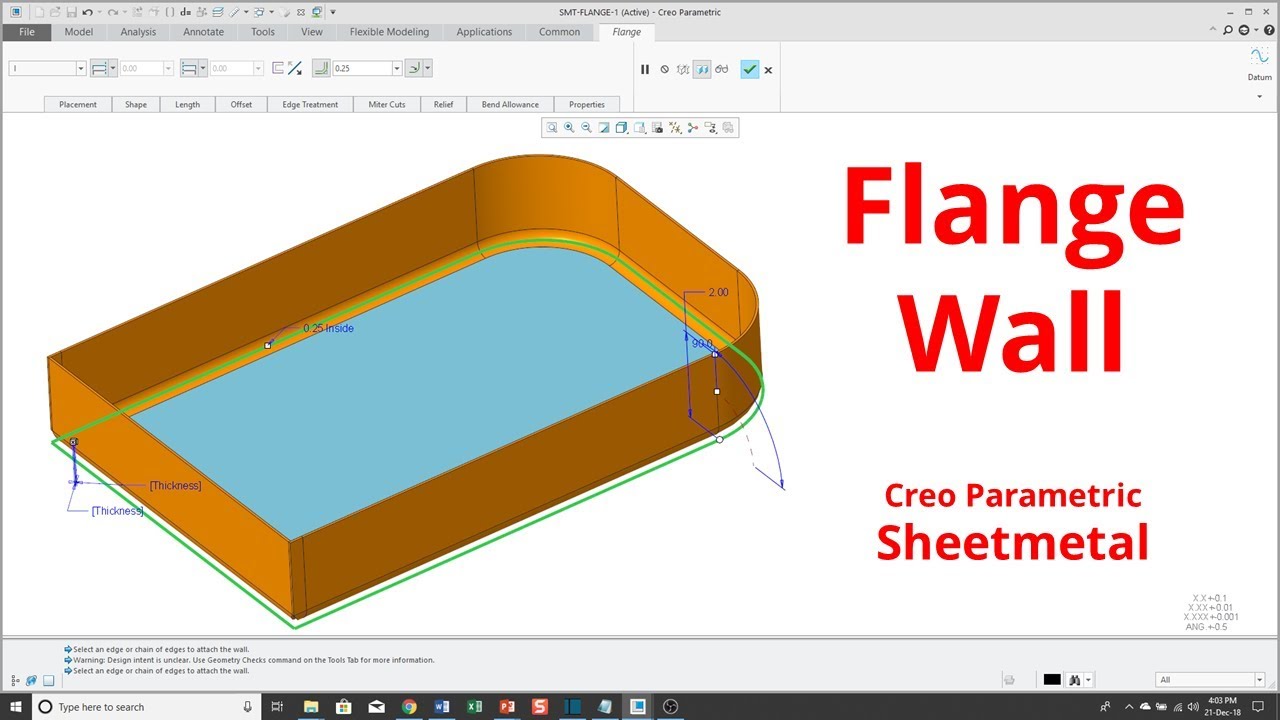

The other thing i did was to create a flange wall in every sheet metal wall.

Here is the basic explanation for the two sheet metal options.

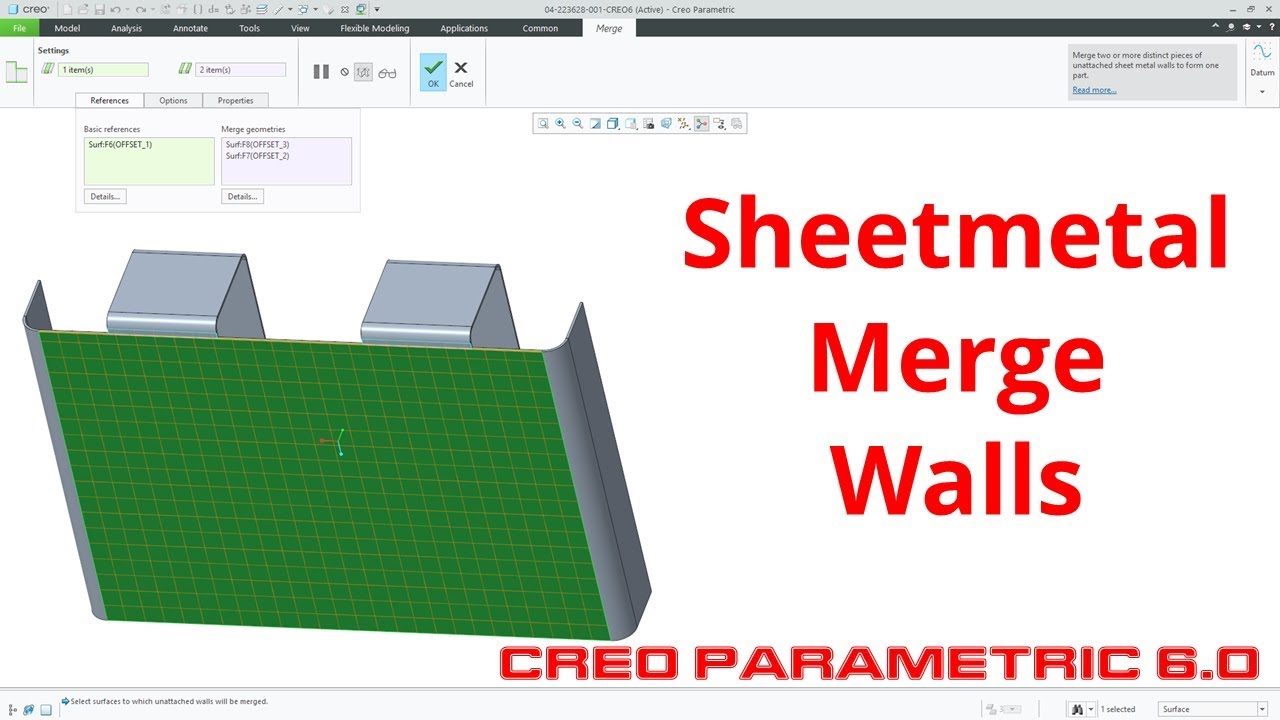

Specifically topics covered include.

72 1 8 is slight short 5 72 may not be exact.

Changing a bend with the constant flange length option selected.

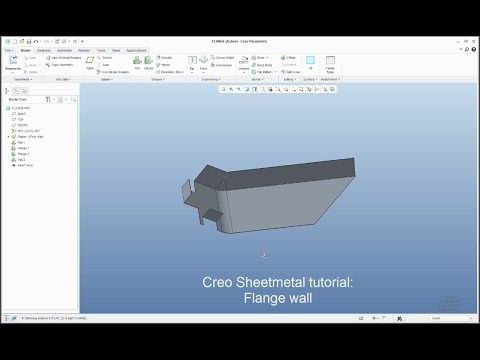

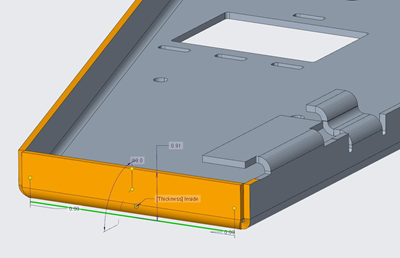

Below is the basic example of the flat and flanged walls.

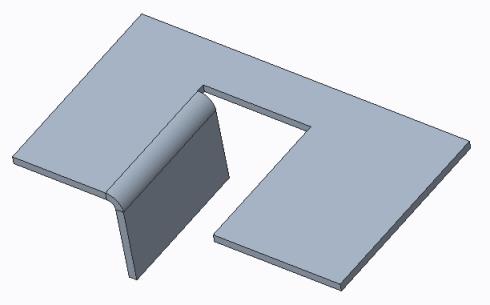

This part is either coined or rolled with a hem tool.

Constant flat length ensures that the length of the unfolded wall is not changed.

View the full course.

A ptc technical support account manager tsam is your company s personal advocate for leveraging the.

Constant flange length keeps the distance between the apex and the end of the wall fixed.

I did some iterations to get the numbers to match ie.

In the formed section this happens three times so creo would have to remove two extra bend allowances to make the part flat.

Please log in to view the full article.

The picture shows the part and the tool that is is formed on.

That s what forms the gap is a rip is added the subtraction of.

It purely depends upon the shape of the part that decides which one to use.

Flat wall gives you control over the profile of the wall.

Sorry to say but i thought this was a cool feature but it came totally useless to me as i cannot show the bending axis as in a regular flange wall.

Information regarding the difference of flange and flat wall features for sheet metal.

The perimeter is curved and there are a lot of relief cuts in the part.

Flange is improved in sheetmetal design.

I already have the flat pattern geometry including the flange.

Changing a bend with the constant flat length option selected.

Flange wall gives you control over the cross section of the wall.

Hi everyone i m trying to model a sheet metal part with a complex flange around its perimeter.

Paul sobejko s suggestion is correct and to work through the reason each bend in sheet metal stretches the metal.

Then you can show that axis in the drawing.

Edge treatment is improved when defining a flange feature.

This tutorial is part of a course.

When modeling sheet metal you always have to be aware of the process used to fabricate the part.

In creo if you use a form tool feature it will not account for the additional material in the flat pattern.