It is based on state of the art product development methodologies and enhanced in order to optimize the product development process of integral bifurcated sheet metal parts.

Processing sheet metal algorithms.

We can cut and bend your sheet metal into the form you request.

Aside from distribution of sheet metal hansen steel also provides metal processing services.

Into each product quality.

Welcome to california metal processing.

Large size sheet metal.

Best lead in point with reduced speed.

Cnckad for laser together with autonest is your best solution for sheet metal processing with laser cutting machines handling most precision laser cutting projects.

A scheduling method using genetic algorithm and dispatching rule for sheet metal processing 2016 international symposium on flexible automation isfa 2016 in the sheet metal processing nesting and scheduling are important design and operational tasks respectively.

Through nct cnc punching laser laser cutting machine cnc bending machine tools rivets and other processing tools for processing sheet metal generally used for sample production the cost is higher.

Coil processing materials hansen steel holds a variety of basic metal coils in stock in our los angeles area california facility including.

1525 x 3050 mm.

We provide the following sheet metal fabrication services.

Based on cutting tables for optimal tool path and cutting parameters cnckad automatically generates the best technology for your laser cutting machine.

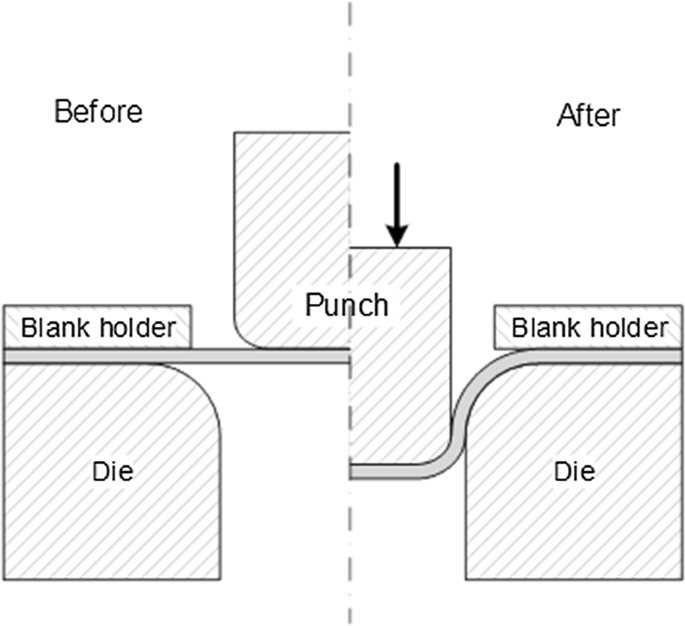

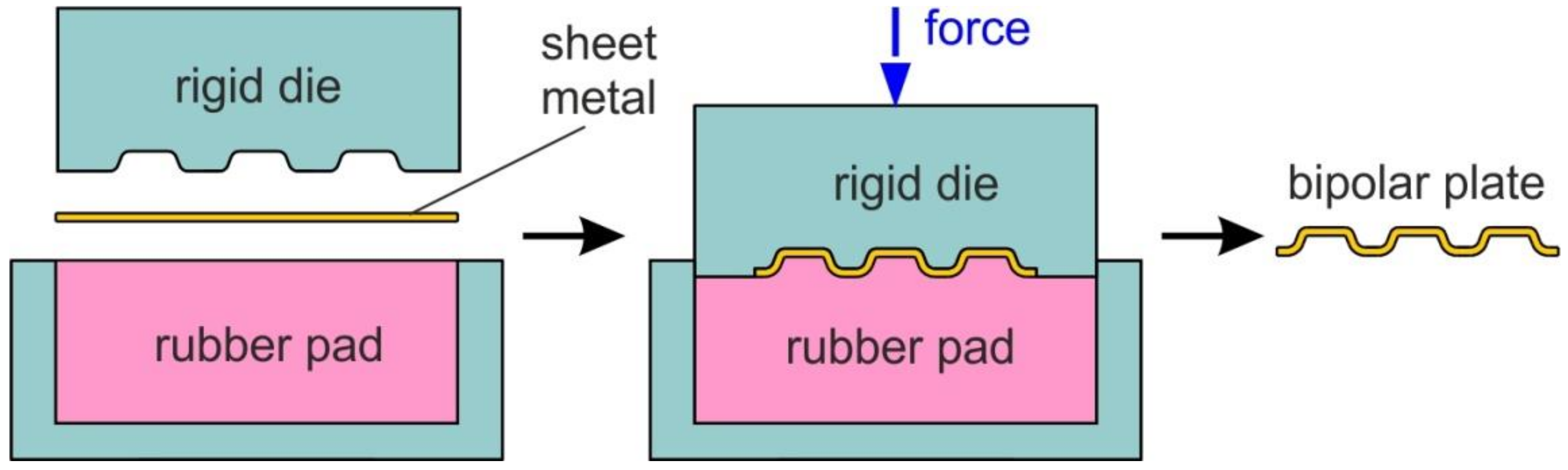

It forms a part by using di erent tools to punch holes in the metal sheet.

Local delivery is offered please call to check availability.

Into each accomplishment gratitude.

Into each employee dignity.

Request pdf algorithms for sheet metal nesting this paper discusses the problem of minimizing the cost of sheet metal punching when nesting batching orders.

Bring in your blueprints or cardboard drawings and we ll cut and form the metal to your specifications.

Coil processing capacities generally encompass from 36 wide to 72 wide though both larger and smaller widths have been leveled and sheared.

By moving the sheet and cutting holes next to each other see figure 1 the press forms the part s outline leaving small pieces to hold the part in the sheet.

Within the collaborative research center 666 the algorithm based product development process has been established.

Structural steel high grade steel aluminum copper brass.

During this process the press follows.

We offer a healthy variety of services.

Approved by nadcap and many other leading companies in the industry.